The Importance of Sustainability in Business Management

Sustainability has become much more relevant for companies and their management nowadays. It is an economically and competitively differentiating factor. The reduction of climate-damaging emissions through the increased use of renewable energies does not only have altruistic motives. Manufacturing companies in Germany face tough, international competition, and energy costs play a significant role in how successfully the respective company can assert itself in the market.

According to a current PAC study (IT & Sustainability – Reifegradindex 2023), for 90% of the companies surveyed, the competitive advantage through the benefits that arise from implementing sustainability is at least an important driving factor. For 70% of companies, concrete cost savings are an important aspect of ESG transformation (ESG: sustainability in the areas of environment, social, and governance).

When you look at the energy costs and specifically the electricity price level, the difference becomes clearest in an international comparison. Consumers in this country pay the highest electricity prices in the world and, on average, 31.80 Euro cents per kilowatt hour, 174% more than in the rest of the world.

Addressing Competitiveness and how Auvidea Achieved CO2-Neutral Production

For German companies, the average price for industrial electricity is 20.3 Euro cents per kilowatt-hour, which is on par with the EU average. However, a current study (vbw – Internationaler Energiepreisvergleich für die Industrie, October 2023) points to a clear discrepancy compared to America and Asia. The industrial electricity price there is on average 8.4 Euro cents per kilowatt-hour. Therefore, many companies in Germany are concerned about their competitiveness. Almost a third of industrial companies (source: DIHK, Aug 2023) are planning or already implementing a relocation of production capacities abroad.

As a company aware of its responsibility, Auvidea is responding to this trend with technical innovation and is taking a different path. Our goal was to achieve CO2-neutral production. We have already achieved this goal in 2021. But how did we do that?

Key Initiatives in Achieving CO2-Neutral Production

- SMT Production: We use vapor ovens, which, in contrast to reflow ovens, have significantly lower power consumption (10 kW vs. 100 kW).

- Office: Computers, servers, and lighting have been optimized for energy efficiency.

- Electrically Powered Company Vehicles: In 2021 we started with two vehicles. The fleet now consists of 8 fully electric powered vehicles.

- Heating and Cooling: We use the waste heat generated during the production process. Heat pumps, underfloor heating, and air conditioning are also utilized.

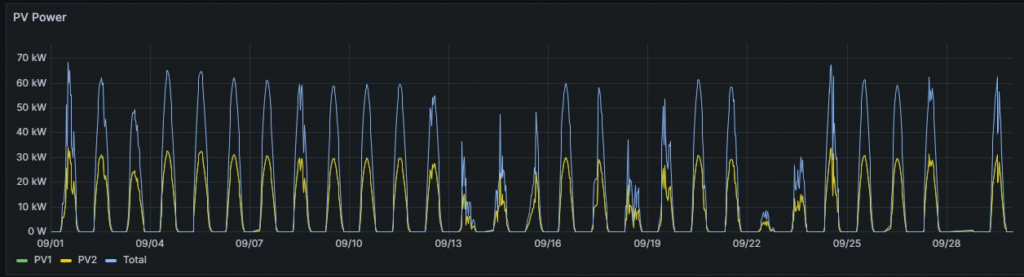

Electricity generation through photovoltaics

With a total of 278 solar panels on the roof and on the wall of our company building, we can currently achieve a theoretical maximum output of 85 kWp. Due to the orientation of the modules, the inclination of the roof (12°), and the outside temperatures to be taken into account (heating of the panels), we are currently reaching a peak of almost 70 kW.

In 2021, for example, we generated a total of 97,221 kWh of electricity through photovoltaics. We consumed 34,113 kWh during this period. 63,108 kWh were fed into the grid. The electricity purchased in 2021 was a total of 41,190 kWh.

| Auvidea | 2021 | 2022 | 2023 |

|---|---|---|---|

| total generation | 97,221 kWh | 106,350 kWh | 96,054kWh |

| self usage | 34,113 kWh | 43,023 kWh | 44,424 kWh |

| feed-in | 63,108 kWh | 63,327 kWh | 51,630 kWh |

| electricity procured | 41,190 kWh | 40,452kWh | 52,740 kWh |

For 2024, we plan to further expand overall performance but, above all, to install an intelligent battery storage solution. This solution will enable us to no longer purchase external electricity, feed electricity into the grid when it is actually needed and also provide emergency power for the production lines.

Conclusion

Even within Germany, it is possible for companies to significantly reduce energy costs. Companies in this country have also learned to use energy very economically. If you look at the relocation trend from a global perspective, it even has negative effects on the energy balance. German companies have learned to use energy very efficiently.